Research data show that fuel efficiency of an automobile can increase by 6%-8% if weight of the complete vehicle decreases by 10%.

Environmental protection, energy saving, consumption reduction and pollution reduction are an important subject for China and even the world. Enhancing fuel economy and reducing exhaust emission of automobiles are one of important measures. Automobile lightweight technology plays a crucial role.

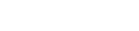

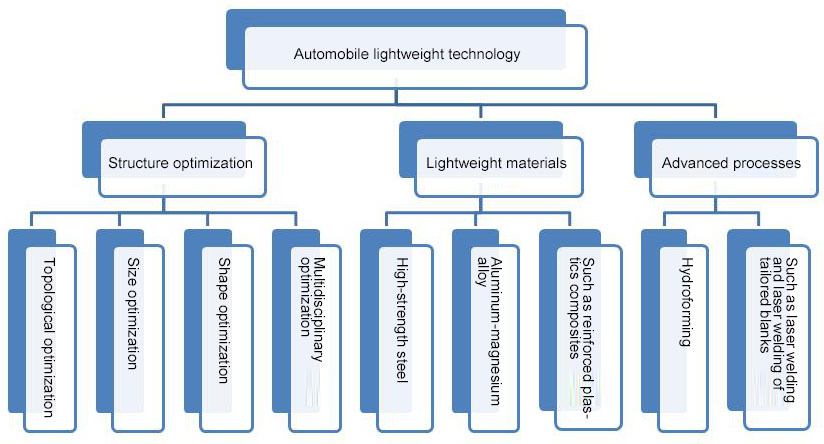

The lightweight concept derived from automobiles and got developed rapidly in automobiles. The main idea is to reduce the curb weight of an automobile as much as possible under the precondition of ensuring strength and safety performance of the automobile. Automobile lightweight technology is mainly reflected in three aspects: structure optimization, lightweight materials and advanced processes.

Structure optimization: Realize reduction of the curb weight through such methods as body frame structure optimization and reasonable layout of key components.

Lightweight materials: Use such light materials as high-strength steel, aluminum-magnesium alloy and high-strength composite plastics.

Advanced processes: Adopt such advanced processes as hydroforming and laser welding to avoid increasing extra weight.

In the above content, it seems that there is no much relationship between automobile lightweight technology and the crane industry.

Since January 1, 2014, it is not allowed to handle registration and licensing for automobiles whose total weight is over 55t including all terrain cranes in China in accordance with the national regulation.

Since the regulation was adopted, sales of large-tonnage all terrain cranes whose dead weight is over 55t have declined continuously. Vehicle overweight, limit on driving on roads and no access to special places have seriously affected normal construction of customers and increased operating cost of hoisting personnel.

Since then, crane lightweight technology has been gradually included in key research projects of enterprises in the industry. XCMG was lucky to take the lead.

Crane lightweight technology

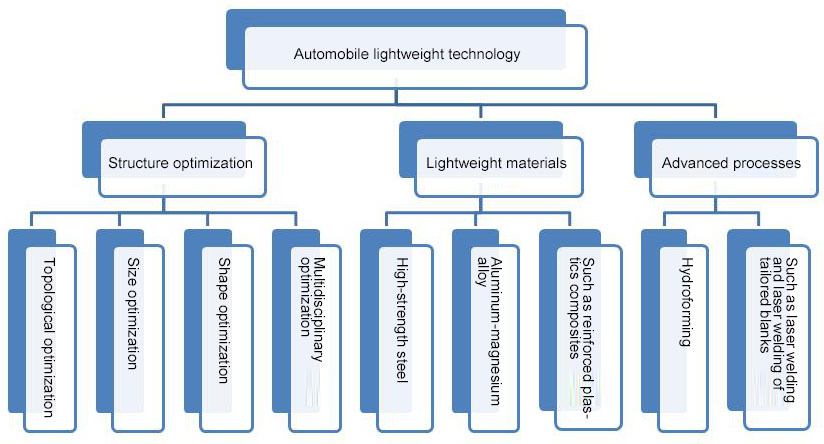

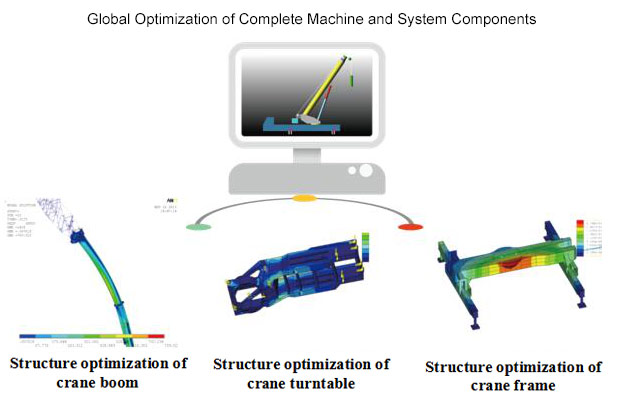

Big differences exist between cranes and family cars. Weight needs to be reduced and big lifting capacity needs to be ensured- this is a contradiction. But XCMG has resolved the contradiction by starting with system optimization and local optimization. At present, all terrain cranes of XCMG whose lifting capacity is 200t or below totally meet the national standard on dead weight under the condition of ensuring performance unchanged.

It is still a tough problem whether dead weight of super-tonnage all terrain cranes whose tonnage is 260t or above can be reduced to less than 55t. There is no precedent internationally. Due to limitations of existing technologies, key components and new materials development, it seems that we still have a long way to go. But the new single engine system created by XCMG, the first one in China, may bring new ideas for the industry.

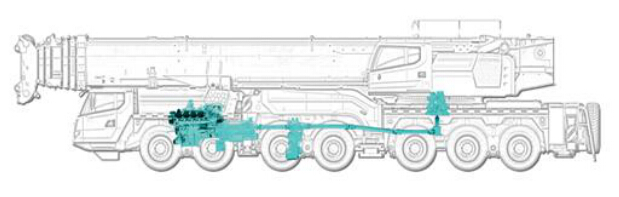

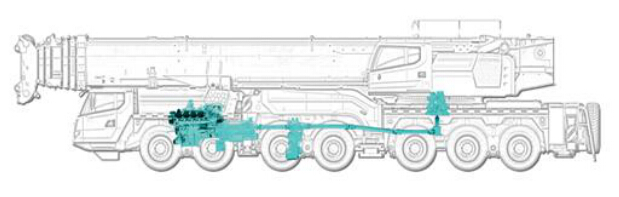

As to single engine system, it means the complete machine uses just one engine. Unlike power transmission of traditional twin-engine cranes through hydraulic system, single-engine cranes realize power transmission through mechanical system which has higher efficiency. Single engine system raises higher requirement for technology, and needs development of new gearbox and driver and innovation of engine energy management technology.

XCA450 is the best embodiment of application of this technology. Its overall performance is close to that of QAY500, but total weight of the complete machine is reduced by 800kg.

XCA450- Weight is reduced by about 800kg and performance gets improved by 5-10% by using single engine system

About crane lightweight technology, perhaps the whole society should make concerted efforts. After all, such projects as high-strength light materials and breakthrough in core components have fields unreachable to the crane industry. But the editor believes that everything will be within reach as the “Made in China 2025” strategy is gradually realized. XCMG will push the wheel of history and develop in its own way.

(The Part 3 ends. The next part of “To Solve Pain Points, See the Seven Highlights of XCMG Leading Technological Innovation Development of the Crane Industry” is coming soon.)