Recently, the 5th Directors’ Enlarged Meeting of the 7th China Machine Building Quality Management Association was held at XCMG. Lu Yansun, Former Deputy Minister of Mechanical Industry and a senior expert consultant of China Machine Building Quality Management Association (CMBQMA); Xu Donghai, Vice Mayor of Xuzhou City; Wang Min, Chairman of the Board and Party Secretary of XCMG; Zhang Weide, Standing Vice Chairman of CMBQMA; Wang Jianhe, Vice Chairman and Secretary General of CMBQMA; Guo Xuejun, Vice Chairman of CMBQMA attended the conference.

Lu Yansun, Former Deputy Minister of Mechanical Industry and a senior expert consultant of CMBQMA gives a speech

Xu Donghai, Vice Mayor of Xuzhou City gives a speech

Wang Min, Chairman of the Board and Party Secretary of XCMG gives a speech

Zhang Weide, Standing Vice Chairman of CMBQMA, gives a speech

XCMG Excavator Machinery and XCMG Hydraulics are honored to win “Quality Award of National Machinery Industry” for the year 2018

Song Zhike, General Manager of XCMG Excavator Machinery, accepts the award and shares his experience

At the Meeting, the organizational and individual winners of National Machinery Industry Quality Award for the year 2018 were commended. XCMG Excavator Machinery and XCMG Hydraulics are honored to win “Quality Award of National Machinery Industry” for the year 2018. Song Zhike, General Manager of XCMG Excavator Machinery, and Chen Dengmin, General Manager of XCMG Hydraulics accepted the award. Song Zhike shared his experience in his speech themed “excellent performance mode of XCMG Excavator Machinery”.

The national machinery industry quality award is the highest quality award of the mechanical industry approved by the State Council and organized by China Machine Building Quality Management Association. The award is granted in accordance with the excellent performance evaluation code once every year. It is a supreme honor for domestic machinery industry enterprises implementing excellent performance management and achieving remarkable performance in quality, economy and social benefits.

XCMG Excavator Machinery and XCMG Hydraulics closely follow the national planning for high-quality development of manufacturing industry to constantly improve and strengthen excellent performance management. Since XCMG Excavator Machinery introduced excellent performance mode in 2011, it has been conducting all-round analysis, diagnosis and evaluation from seven aspects: leadership, strategy, customer and market, resources, process management, measurement analysis and improvement, and operation results to conduct a comprehensive analysis on the evaluation and diagnosis, and making constant improvement by using advanced methods such as lean management and six sigma so as to enhance the maturity of the company’s operation and management and core competitiveness, granted the title “national advanced enterprise implementing excellent performance mode” multiple times.

Dedicated to groundbreaking technological innovation

Deploy a global collaborated R&D system

XCMG Excavator Machinery deeply practices the product concept of “advanced technology and durability” to achieve its sustainable development goal, committed to creating a R&D system with groundbreaking technological innovation strength. This system, cored by innovation and closely centered on the national strategy and customer demand, aims to deploy a globally collaborative innovation system, and strive to break through a batch of key core technologies and major technology projects, a batch of scientific and technological transformation achievements and core patents as well as a batch of technical standards that influence and drive the development of the industry.

Since the implementation, continuous technological innovation has effectively promoted the industrialization of excavating machinery, the developed product models have covered from 1.5-ton to 700-ton hydraulic excavators, and the products are sold to all over the world's five continents; 7 scientific and technological innovation achievements have won provincial or above mechanical industry science and technology awards, including 3 national awards; the Technical Conditions for Earthmoving Machinery-- Hydraulic Excavator drafted and revised by us has been successfully released, driving high-quality development of the industry with innovative strength.

In order to promote core technology breakthrough, XCMG Hydraulics has built the first comprehensive test platform for hydraulic components in the industry, relying on the index system of hydraulic components to achieve a full life cycle data management; it has been actively promoting digital research and development, creating the industry's first intelligent design platform (CICDS) integrating design standards and product standards to realize research and development efficiency and accuracy through four functional blocks; it will continue to increase investment in R&D, and establish strategic alliances for technological innovation with colleges, research institutions and enterprises at home and abroad to concentrate superior resources to achieve key breakthroughs.

Focus on upgrade of lean smart manufacturing system

Create first-class manufacturing bases

XCMG Excavator Machinery introduces and promotes lean manufacturing management in an all-round and systematic way. It, centering on the value chain mainly composed of suppliers, XCMG Excavator Machinery and customers, tries to establish a lean manufacturing management system constituted by eight sub-systems including total flow management, total quality management and total production maintenance as well as the supporting measurement and evaluation system and visual Kanban management system for five categories of lean performance indicators: quality, safety, efficiency, capability and improvement.

Intelligent production line of XCMG Excavator Machinery

XCMG Excavator Machinery has also established a set of modes and methods for in-depth integration and collaborative advancement between lean production and intelligent manufacturing. The intelligent equipment accounted for more than 70%; key manufacturing process like welding, machining, coating and assembly as well as the intelligent operation and lean performance indicators of the lean manufacturing system have achieved leapfrog progress, ensuring the high quality, high efficiency, high speed and flexibility of the whole product manufacturing process.

In 2016, our lean management achievements won the first prize of the 22nd national enterprise management innovation achievements assessment; in 2018, XCMG Excavator Machinery was recognized as a “green plant” by the Ministry of Industry and Information Technology, and passed the evaluation of the national “industrialization and informatization integrated management system”.

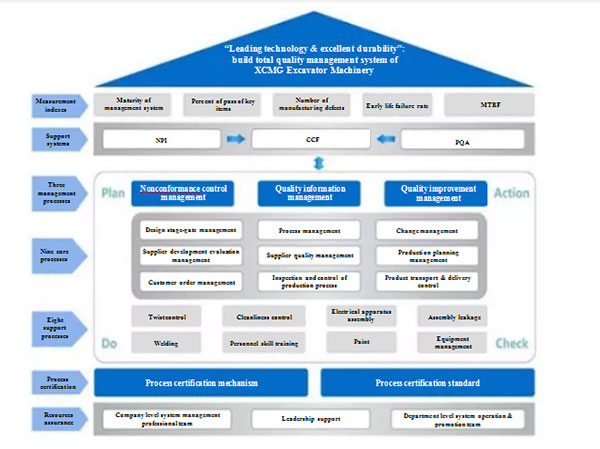

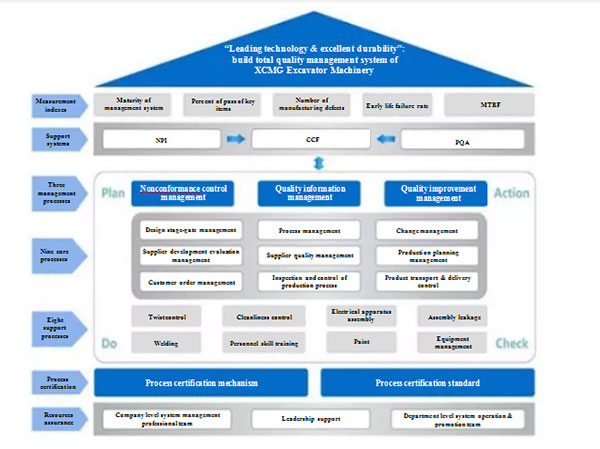

Total quality management system of XCMG Excavator Machinery

As the concept “intelligent manufacturing” emerges, XCMG Hydraulics makes breakthrough from such aspects as “automation, informatization and intelligence” by widely applying automated and intelligent devices including CNC, welding robots and intelligent logistics system to upgrade the existing manufacturing process, and using management systems like SAP, ERP and informationized management software to advance in-depth integration of informatization and industrialization.

Intelligent electroplating line of XCMG Hydraulics

XCMG Hydraulics has been dedicated to taking a featured intelligent manufacturing development path, outputting technologically advanced and durable intelligent products, and making up for the short slab of equipment manufacturing in basic components and parts. In 2017, the company, as the only winner of “pilot demonstration of intelligent manufacturing” and “pilot demonstration of industrial Internet applications” in the industry, was invited to attend the 19th China International Industry Expo to showcase to the world the whole life cycle intelligent services of XCMG products and the latest strength of industry chain collaboration as we as new thinking on cutting-edge information technologies such as intelligent manufacturing, Internet and big data.

Adhere to customer-orientation

Build a total quality management system of whole value chain coordination

XCMG Excavator Machinery vigorously pushes forward the construction of the internal and external quality information integration, improve customer satisfaction feedback platform, pilot a quality information feedback channel for typical agents in five zones, and construct information transmission channels for customer complaint information and overseas fault information. It strengthens the quality improvement of suppliers, collaborates with suppliers through targeted analysis and targeted matching, and regularly formulates special quality improvement plan. It sets up quality information management system, utilizes all kinds of quality technologies and tools, and improves the quality improvement processes and standards based on data analysis for the whole process. It establishes a quality cost evaluation system for single products in their whole life cycle, providing support for new product development, product upgrading and marketing policy formulation.

XCMG Hydraulics resolutely implements the action spirit of “quality is life”, innovating the establishment of hierarchical audit and management system, quality management maturity evaluation model and quantitative evaluation standard centered on customer satisfaction, carrying out 3C service brand cultivation (3C: super collaboration, super accuracy, super value), and striving to achieve the double improvement of management quality and physical quality.

In recent years, the quality of XCMG products has been steadily improved, and the overall user satisfaction has reached the first-class level in the industry according to third-party evaluation. The 300h failure rate of XCMG excavator products has been further reduced, with a year-on-year decline of 12%. The mean first failure time has been continuously improved, with a year-on-year increase of 10.4%. XCMG hydraulic cylinders are recognized by customers for a durability of 10,000 hours. In 2017, XCMG Excavator Machinery and XCMG Hydraulics won the quality award granted by Mayor of Xuzhou City. In 2018, XCMG Excavator Machinery won the first prize of quality technology award of China Association for Quality.