GBA (Guangdong-Hong Kong-Macao Greater Bay Area) is the fourth largest bay area in the world after the New York Bay Area, San Francisco Bay Area and Tokyo Bay Area. It is one of the most economically active areas and important growth pillars throughout the country. The construction of GBA is a major national strategy, which is of great significance to enhance Hong Kong and Macao’s participation in the national development, enhance competitiveness and maintain long-term prosperity and stability.

Recently, 100 sets of XCMG V7 light-weight mixers have been satisfactorily delivered to Shenzhen Henglilong Group. The delivery of 100 sets of mixers has aroused great repercussions in Shenzhen area, which also marks that more and more XCMG V7 concrete machinery products have entered Guangdong market and actively contributed XCMG’s strength to the construction of GBA.

Shenzhen Henglilong Group is a large-scale concrete manufacturer with the strong capacity in Shenzhen. At present, it has 6 mixing stations and more than 200 mixing trucks, and has participated in various major Construction projects in Shenzhen, such as Shenzhen Convention and Exhibition Center, Shenzhen-China Channel and other national key projects.

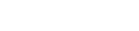

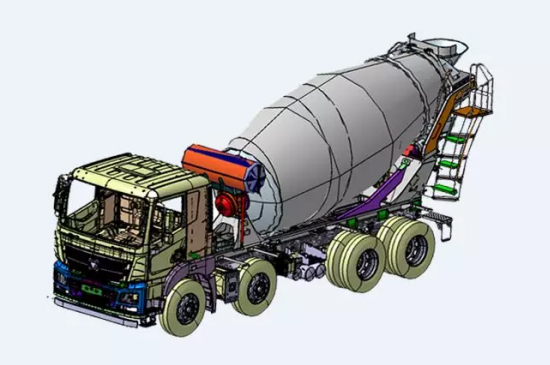

The mixer delivered this time is a light-weight of XCMG V7, which is thoroughly matched with XCMG’s new Hanfeng chassis, equipped with G5 cab and classic power train, and is safe, comfortable, reliable and economic. These mixers have outstanding performance in the energy conservation, environmental protection, convenient maintenance, safe operation and efficient management.

XCMG V7 mixers are based on the market and customer demand. They are thoroughly upgraded in terms of product safety, environmental protection, reliability and convenience.

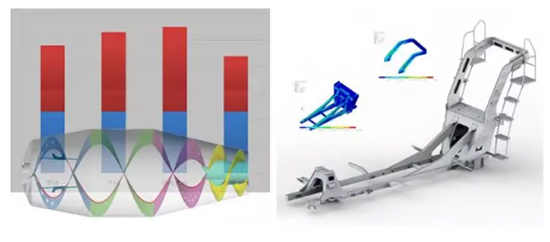

“Light-weight” shows XCMG’s R&D strength and embodies energy conservation and environmental protection. The coordinated design of the top and chassis has realized the optimal weight allocation of each module. The lightweight technology application of engine, transmission case, suspension, hub and other components, specialized design of wheelbase, crossbeam, front suspension and rear suspension, topology optimization of frame, selection of high-strength and wear-resistant materials for barrel, etc. have created a highly competitive lightweight complete vehicle in the industry, with the same load volume, lighter weight and lower oil consumption as compared with peers.

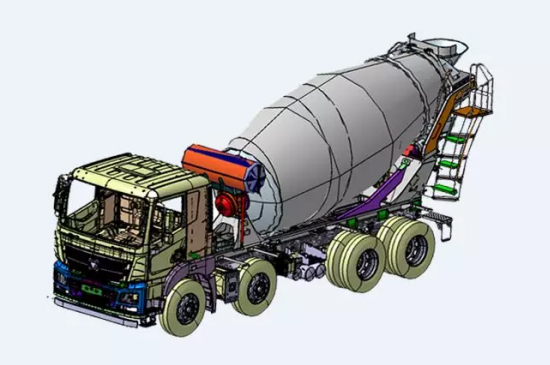

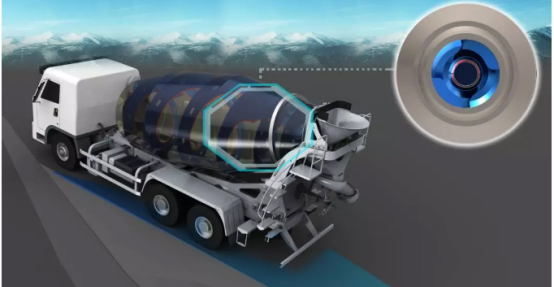

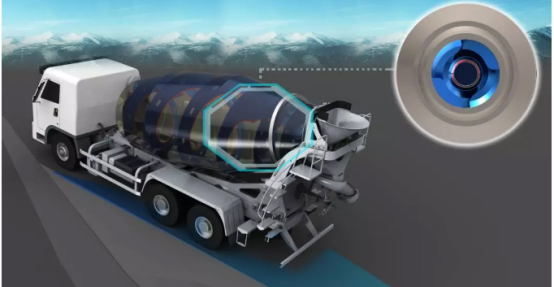

XCMG V7 mixer truck has become a model in the industry with the features of “fast feeding, even mixing and thorough discharge”. Continuous trace + large rise angle design of front cone, concrete slump change range ≤5% at each stage, residual rate ≤0.4%; with the application of the rear cone curved blade technology with large bending angle and independent intellectual property rights, the feeding and discharging speed has been increased by 10%. Sealing blade technology + barrel low inclination design, the inclination angle of the same loading volume is 5% lower than that, of peers, and the stability is improved by 18%.

XCMG V7 mixers are thoroughly upgraded in reliability, with lower customer maintenance and operating costs. The tank body and blade plates are optimally matched to realize the life design of the stirring system. Integrated subframe + triangular cable-stayed beam, super load-bearing, reliable and durable; the professional wear-resistant lining board of the feeding and discharging system is applied, and the service life is prolonged by 50%.

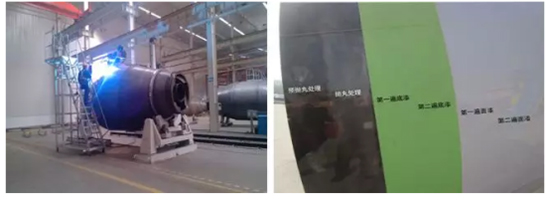

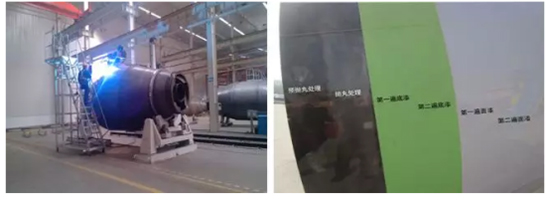

In addition, German manufacturing and acceptance standards have been thoroughly introduced, and tank selection materials + special equipment + special tooling have higher manufacturing accuracy and more reliable structure. The coating adopts the process of double polishing + double bottom + double surface coating, with good paint quality and longer service life. Digital assembly line of the whole machine, assembly quality is more stable.

XCMG V7 mixer truck is a direct embodiment of XCMG Schwing landing “leading in technology, not destroyed” to make handicrafts, and is also a vivid interpretation of practicing the product concept of “German technology, made in China, excellent quality”. XCMG V7 Mixer, which integrates the German SCHWING technology, polishes the details with ingenuity and pursues perfection with details. It is more advanced in technology, more reliable in quality, more stable in performance and more exquisite in models.