In recent years, as clean energy sector grows, especially a booming wind power segment, China had been the world’s largest wind power market by 2017 for 9 consecutive years.

Due to excessively demanding requirements of treacherous operation settings on products, wind farm installation has long been an industry of both high risks and high rewards. Installation equipment must meet more than one higher requirement: large hoisting capacity, strong wind resistance, higher site adaptability, convenience in site change and higher efficiency.

【Superlarge Hoisting Capabilities & High Operation Precision】

With a special wind power arm frame, QAY1200A has a superlarge hoisting capability for lifting any wind turbines of up to 2.5W. It can easily lift a load of up to 90 tons for the lifting height of up to 110m, or a load of up to 106 tons for the lifting height of up to 104m. Despite being a years-old model, it has an excess capability and operation precision reserved for any wind turbines of up to 2.0/2.5MW which are becoming mainstream ones overtimes due to its futuristic design, as a result, having a larger performance leeway and safety coefficient than that of rivals of its kinds.

Meanwhile, thanks to its strong amplitude performance and a larger operating range, it can lift other accessories such as blades within the range of 0-56m, as a result, effectively solving the issue of transporting a blade into the installation site.

【High Safety & Worry-free Operations】

Unlike the pillar structural design widely used in the sector, where repeated adjustments of pillar positions and elevation angles of the main boom are needed to ensure the COG of the entire equipment falls within the range circled by the outriggers so as to prevent against any turnover, QAY1200A’s double oil cylinder-supported luffing boom enables any luffing to be completed at a stroke, making the lifting operation quicker and more stable.

Furthermore, with an arm head of lattice boom structure and a powerful telescopic boom, , QAY1200A is lighter and free of any risks while the boom is extending/withdrawing.

According to complaints from users, the pillar structural design, which is widely employed by all equipment suppliers except XCMG, is prone to obviously distorting the field of vision and having additional safety hazards due to an uneven distribution of gravity.

QAY1200A is perfect in terms of operation safety: while extending to its full length at a superlift, the main boom forms a triangle with boom supports, leading to a more stable structure and a powerful wind-resistance ability.

【Limit Design Idea & High Cost Efficiency】

Narrow Roads, steep slopes and limited operating spaces are major constraints to the full play of a crane's performance.

Since 4m-wide hillside roads are surely inaccessible to a super-wide crane, the equipment has to be torn down, and then, assembled, leading to a higher operation cost and a longer operation period. With an overall width of less than 3m both while traveling or changing sites, QAY1200 can easily have an access to any construction sites and highways.

【Unrivaled Operation Efficiency】

According to industry insiders, QAY1200A had installed nearly 100 wind turbines in total in a short span of 10 months, setting a way far record for the sector since its boom in 2008.

Besides being comparable to small cranes in the trouble-free continuous operation time, it has a supreme reliability.

As we all the professionals know, there is only 12 hours or so in a day suitable for wind power equipment installation. Apart from the tight timeframe, the primary critical factor influencing the installation progress is the crane. It must be quick to dis/assemble and have higher efficiency in loaded short-distance transportation.

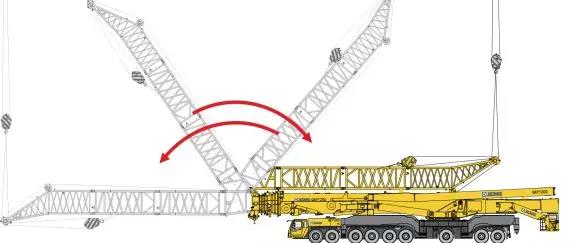

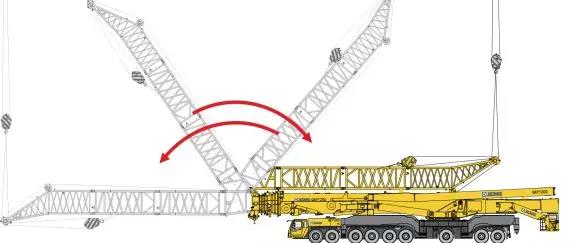

With the globally pioneering design: folding wind power crane jib, QAY1200A makes it easy and convenient to ply between equipment bays: Only balance weights are to be taken down, and the wind power crane jib may be folded and transported easily along with the main body of the equipment, enabling you to complete the whole process from the disassembly to reassembly within 4 hours.

Besides, it also leads to a lower transportation cost, as only 5 flat-bed trailers are enough for the job of transporting all the components all at once.